Fig. 1 The late Peter ‘Micky’ Willet (deceased April 2019) in the Plowden & Smith metal department cleaning the bore of an antique gun

Introduction

Case Studies

Late 19th Century Ornamental Copper Urn

Fig 2. Victorian ornamental copper urn before (left) and after (right) conservation with Mick Willet, Plowden & Smith’s Senior Metal Restorer for over 50 years

Fig 3. Area of localised patina loss on the base of the urn, caused by the distortion

Fig 4. Micky dismantling the urn

Fig. 5 Differently sized pieces of Jabroc® used by Micky to reshape the urn

Rifles

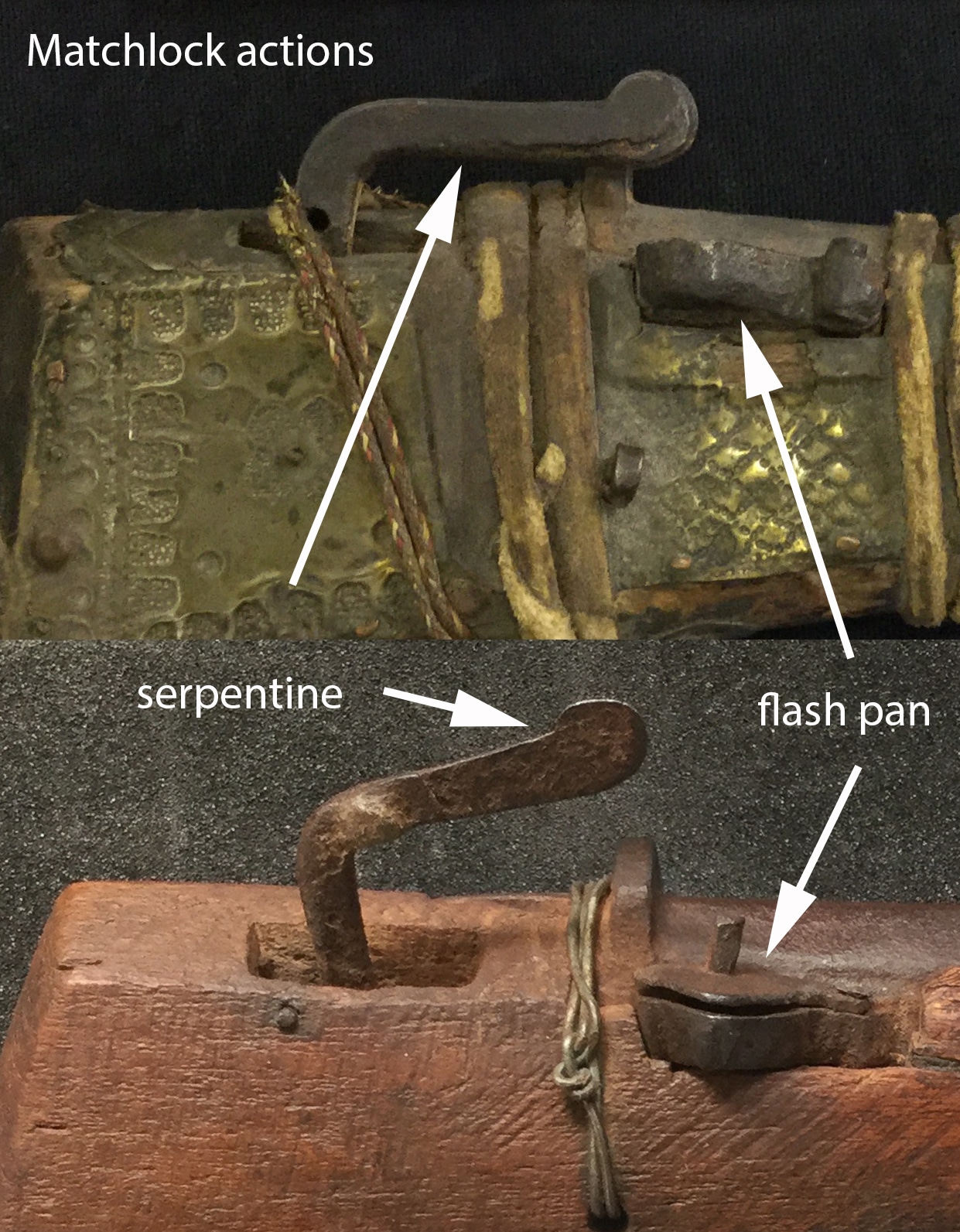

Fig 6. Examples of the oldest form of gun action, matchlock, found amongst modified rifles

Fig 7. This rifle was not dismantled to preserve the raw hide wrap

A large group of rifles for an international client was conserved by Plowden & Smith in 2019.

Although some of the rifles were of entirely relatively recent manufacture, dating from the 20th century and representing a single production, most were a fascinating amalgamation of parts and modifications originating from different guns, time periods and cultures.

In some cases the rifle actions dated back to the 16th and 17th centuries (Fig. 6), and there was a great range in the stability of these composite pieces, often due to the makeshift nature of their creation for urgent use in battle. The specific construction and components represented a fascinating historical resource indicating trade or even trafficking relationships (Grant 2015; Satia 2018).

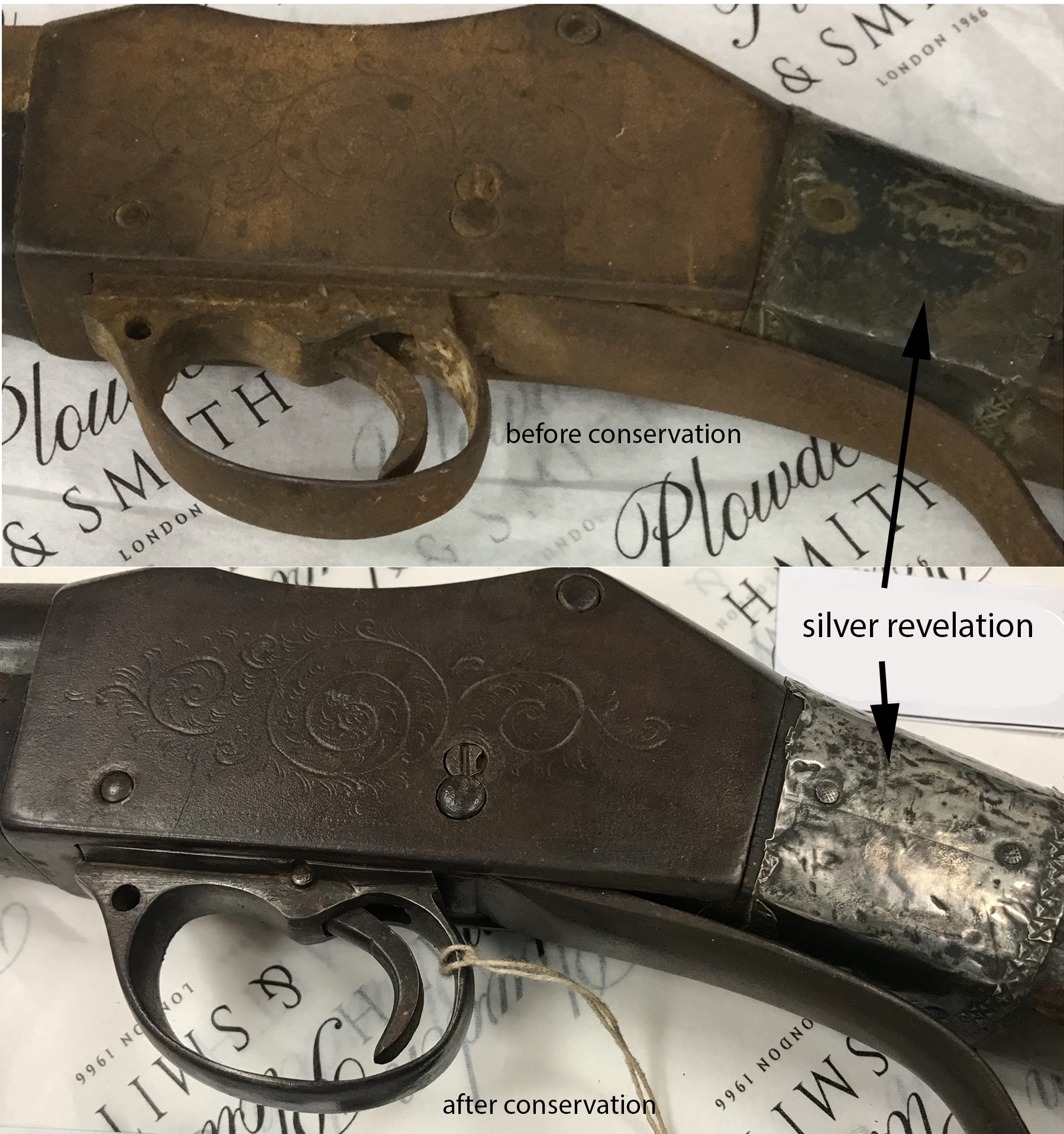

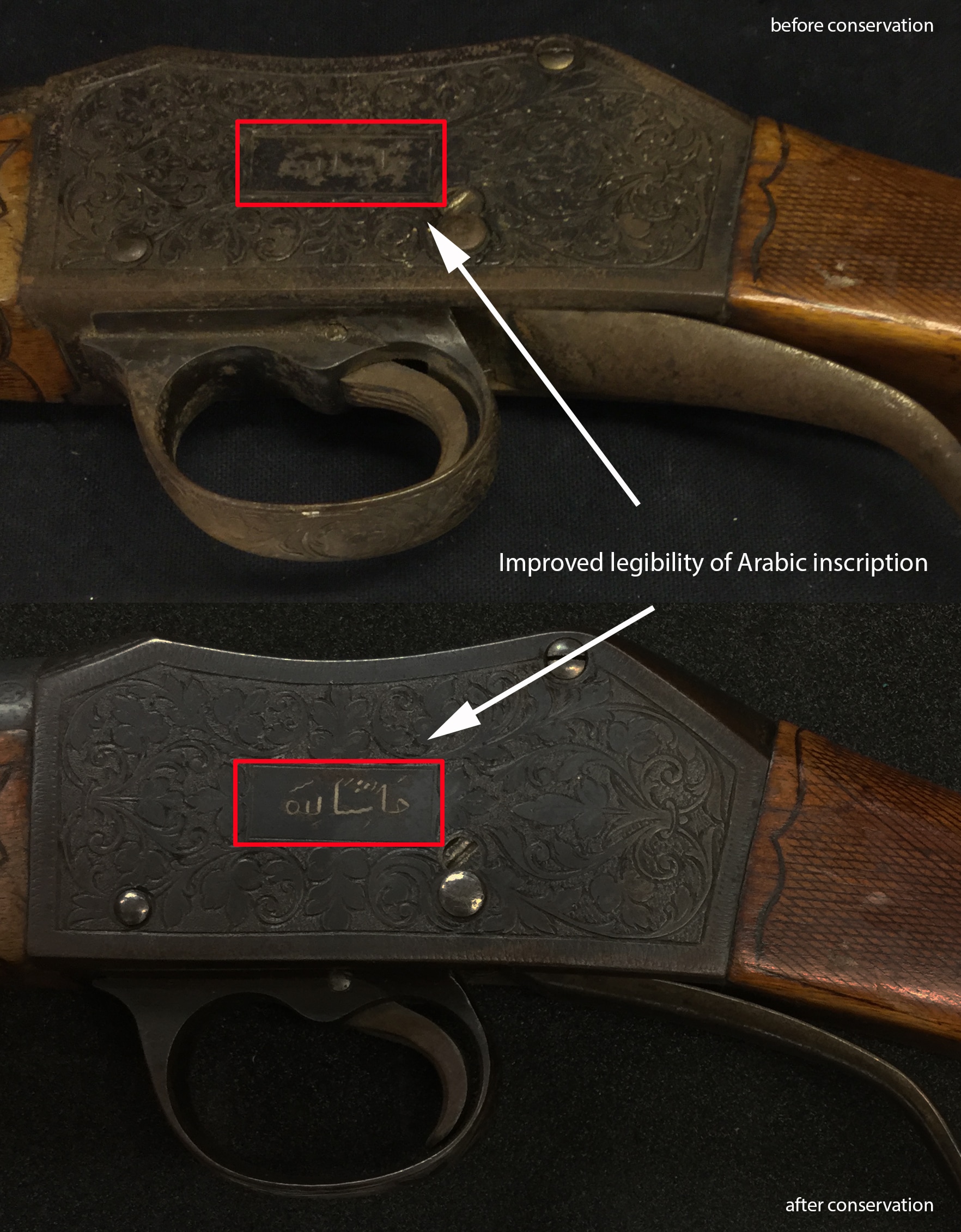

As part of a largely undocumented collection, very little was known about these objects and the client was keen for Plowden & Smith to discover as much as we could about them during their treatment. Ensuring object stability was also key as the possibility of future handling of these items could not be ruled out. Moderate to severe corrosion could be seen on most external surfaces, concealing decorative features and manufacturing details as well as representing a condition issue, and in some cases stability issues were compounded by missing parts.

Some rifles could not be separated e.g. when modifications consisted of raw hide wraps or fragile metal bands (Fig. 7). On all examples condition was much improved through cleaning of external surfaces (Figs. 8 and 9). However, where possible, and under Micky’s guidance, many items were disassembled to thoroughly clean and treat active corrosion on internal as well as external fittings (Fig.10).

This process exposed makers marks not only hidden by corrosion, but also on surfaces not visible when the guns were assembled. This provided valuable information for the client about the date and place of manufacture of different components, and, in some cases, the number of modifications made. Missing screws were also replaced, and Micky made new parts from scratch (Figs. 10 and 11), to support structural integrity and understandability.

Had these pieces been treated with a strictly conservation approach, using contemporary academic skills and adhering to minimum intervention, the guns would not have been dismantled and structural issues would have been addressed using discreet reversible fills and supports. This would not have facilitated the discovery and treatment of a significant proportion of the corrosion; makers marks and the new information they provided would have remained unknown; the final pieces would have appeared noticeably incomplete on display; and materials foreign to the object would have been introduced, in place of the metal fittings which Micky made. It is also arguable that the strength and stability of restored fittings was superior to the alternative fills and supports.

Fig. 8 A before and after cleaning example showing decoration revealed by rust removal and the revelation of a silver decorative panel

Fig. 9 A before and after cleaning example illustrating the improved legibility of a personalised inscription

Fig. 10 Top left – Pieces from a dismantled gun stored carefully during cleaning; Bottom left – manufacturing details on a surface hidden when the gun is assembled; Right – a replacement for a missing part, necessary for stability

Fig. 11 A missing part created by Micky which facilitated the reattachment of the strap

The last case study is a particularly poignant example, as Micky passed away before the planned treatment could take place. This meant that an alternative treatment approach had to be taken, aptly demonstrating the scarcity of knowledge and ability available today to perform traditional procedures.

An ornate chest was undergoing restoration in Plowden & Smith’s furniture department and over 20 fittings were removed for specialist treatment by the metal restoration team. These historic steel items had been tinned at the time of manufacture to protect against corrosion (Vallance 1912, 118-119), however this surface was now badly worn (Fig.12). This had left the steel exposed and vulnerable to degradation. The appearance was also unsightly and not in keeping with the aesthetics of the prestigious official room to which the furniture belonged.

The client required the tinned surface be restored using a process known as tinning. Micky was adept at the traditional hot dip method and it was decided that this would be the optimum approach to produce the best finish whilst remaining sympathetic to the original method of manufacture. This project was also intended to serve as internal continuing professional development (CPD) so that this skill could be shared with other team members.

Without Micky’s knowledge these items ultimately had to be treated using the electroplating process; which whilst still providing the required protection and aesthetic improvement, is perhaps lacking the historic sensitivity of the traditional hot dip method.

Fig. 12 Furniture fittings showing evidence of degraded tinning

Notes

The topic of this blog post was originally presented as a Poster and Flash Presentation at Metal 2019, the Interim Meeting of the ICOM-CC Metals Working Group, Neuchâtel, Switzerland September 2nd-6th.

References

Ashley-Smith, J. 2016. Losing the edge: the risk of a decline in practical conservation skills, Journal of the Institute of Conservation, 39, 2, 119-132.

Chang, T., Wallinder, I., O., Fuente, D., Chico, B., Morcillo, M., Welter, J., M., and Leygraf, C. Analysis of Historic Copper Patinas. Influence of Inclusions on Patina Uniformity. Materials (Basel), 10, 3, 298.

Cortés, L. & Scattolin, M., 2017. Ancient metalworking in South America: A 3000-year-old copper mask from the Argentinian Andes, Antiquity, 91, 357, 688-700.

European Confederation of Conservator-Restoreres’ Organisation (E.C.C.O). 2003. Professional Guidelines.

Figueiredo, E., Silva, R., J., C., Araújo, M., F., and Senna-Martinez, J., C., 2010. Identification of ancient gilding technology and Late Bronze Age metallurgy by EDXRF, Micro-EDXRF, SEM-EDS and metallographic techniques, Microchimica Acta, 168, 3-4, 283-291.

Grant, J., 2015. The Arms Traffic in World History. In: Bruinsma G. (eds) Histories of Transnational Crime, 71-90. Springer: New York.

Halahan, F. 2018. Changes in attitudes and training in conservation, Journal of the Institute of Conservation, 41, 1, 79-84.

E. H. Lehmann, E., H., van Lang, R., Estermann, M., Hartmann, M., LoCelso, F., Kardjilov, N., Tisseyre, P., and Tusa, S., 2016. Bronze Sculptures and Lead Objects Tell Stories About Their Creators: Investigation of Renaissance Sculptures and Ancient Ingots by Means of Neutron Tomography, Neutron Methods for Archaeology and Cultural Heritage, 19-39.

Satia, P. 2018. Empire of Guns: The Violent Making of the Industrial Revolution. Penguin Press: London.

Smith, S. 2008. Preserving and Passing on Heritage Trade Skills, Australian Journal of Multi-Disciplinary Engineering, 6, 1, 111-118.

Téllez, H., Vadillo, J.M., Laserna, J.J., Chater, R., J., and McPhail, D., S. 2012. Multi-analytical study of patination methods on steel substrates: a full insight into surface chemistry and morphology, Analytical and Bioanalytical Chemistry, 402, 7, 2277–2285.

Vallance, A., 1912. Early Furniture-V. Furniture with Applied Metalwork (Continued). The Burlington Magazine for Connoisseurs, 22, 116, 116-119.

Welter, J., M. 2019. Contact tinning: A millennia‐old plating technology. Archaeometry, 61, 906-920.

About the Author

Jill Saunders is Senior Objects Specialist at Plowden & Smith Ltd. (London, UK) focusing on metals conservation, analytical services, and developing collaborations within the museum and heritage sector. She has a BA in The Classical Past from Durham University, an MA in Principles of Conservation and an MSc in Conservation for Archaeology and Museums from the Institute of Archaeology, University College London. She is currently completing PhD research with UCL concerning cleaning of non-ferrous metals. Her research incorporates public perceptions studies concerning preferences of silver tarnish levels on historic silver and cleaning levels on archaeological bronze in different contexts; materials science experimentation into impacts of different cleaning methods on bronze, brass, and copper coupons artificially corroded in different ways; and a professional survey into practice and attitudes about cleaning silver alloy and copper alloy objects. Her special interests also include communicating conservation, public outreach, and the support of community heritage conservation through initiatives such as volunteer training.

Find out more about Plowden & Smith’s Metal Restoration Services

Find out more about Plowden & Smith’s Silver Restoration and Bronze Restoration services