RESTORATION & CONSERVATION SERVICES | DECORATIVE ARTS & OBJECTS | METAL RESTORATION

Metal Restoration

Plowden & Smith is an industry leader in the restoration, conservation and care of metal objects, extending the life of objects and artefacts that are severely damaged, have active corrosion, or are missing parts or historic finishes integral to the object’s stability or ability to function.

Rigorous attention to detail underpins every one of our treatments, which range from brazing, soldering and welding to filling losses and recasting or fabricating replica elements, as well as retouching and re-patinating surface finishes.

We restore and conserve many objects which are made either wholly from bronze and spelter, or which feature bronze and spelter elements. To find out more, please visit our dedicated bronze restoration page.

We are authorities in the restoration and care of antique and contemporary silver – everything from the slightest ding to the most substantial dent is repaired. Our cleaning, polishing and re-plating services utterly transform the appearance of scratched and worn silver objects. To find out more, please visit our silver restoration page.

We are noted for our expertise in replicating specialist or unusual metal finishes, including the patination found on ancient Middle Eastern and South East Asian bronzes.

We carry out small and large metal restoration projects for private individuals, as well as galleries and museums based all over the UK and around the world.

Metal Restoration Case Studies

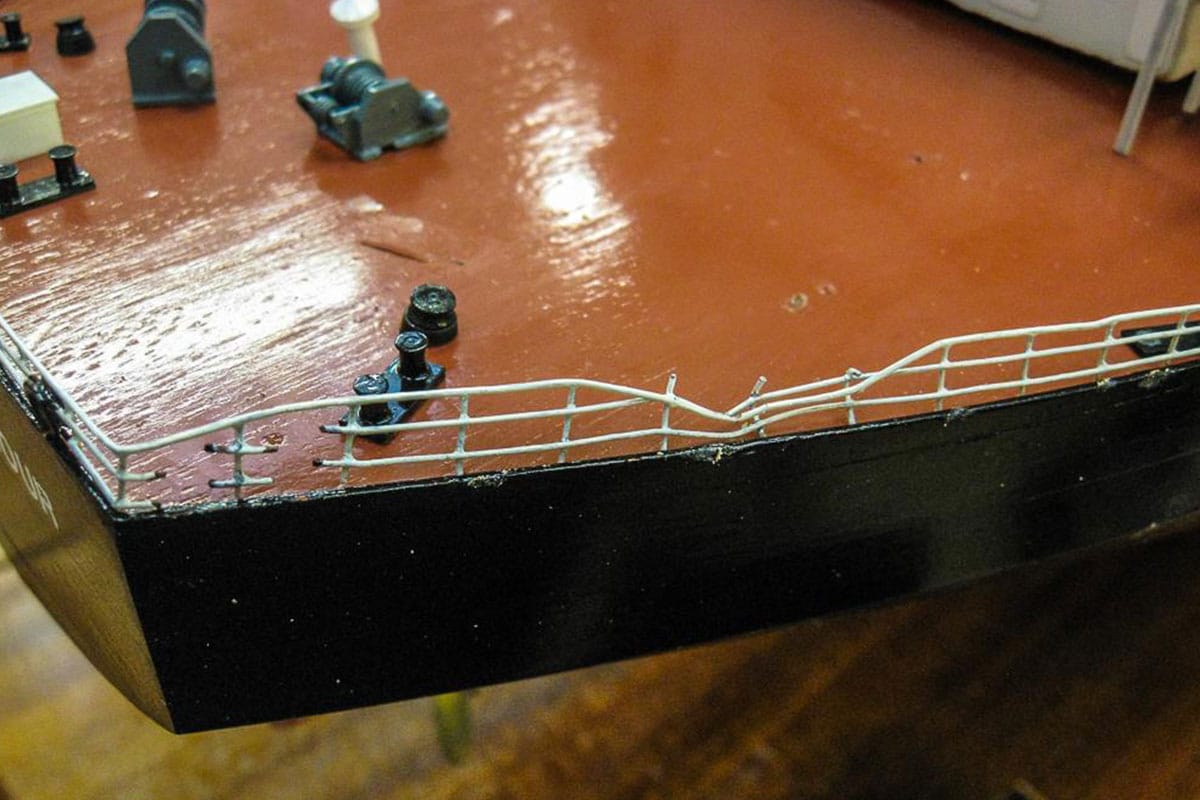

Crude Oil Tanker Model | Metal Restoration Project

This model of a crude oil tanker had been significantly damaged in transit, and required extensive restoration treatment.

The tanker’s super structure had become completely detached and a significant number of smaller plastic, wood and metal components and assemblies (notably ladders, lengths of railings and pipelines) had broken off or become distorted.

It was important to establish the location of each missing part and from there, work out what pieces were missing.

Once this had been done, we could begin restoring the damaged elements, or where needed, creating replicas from scratch.

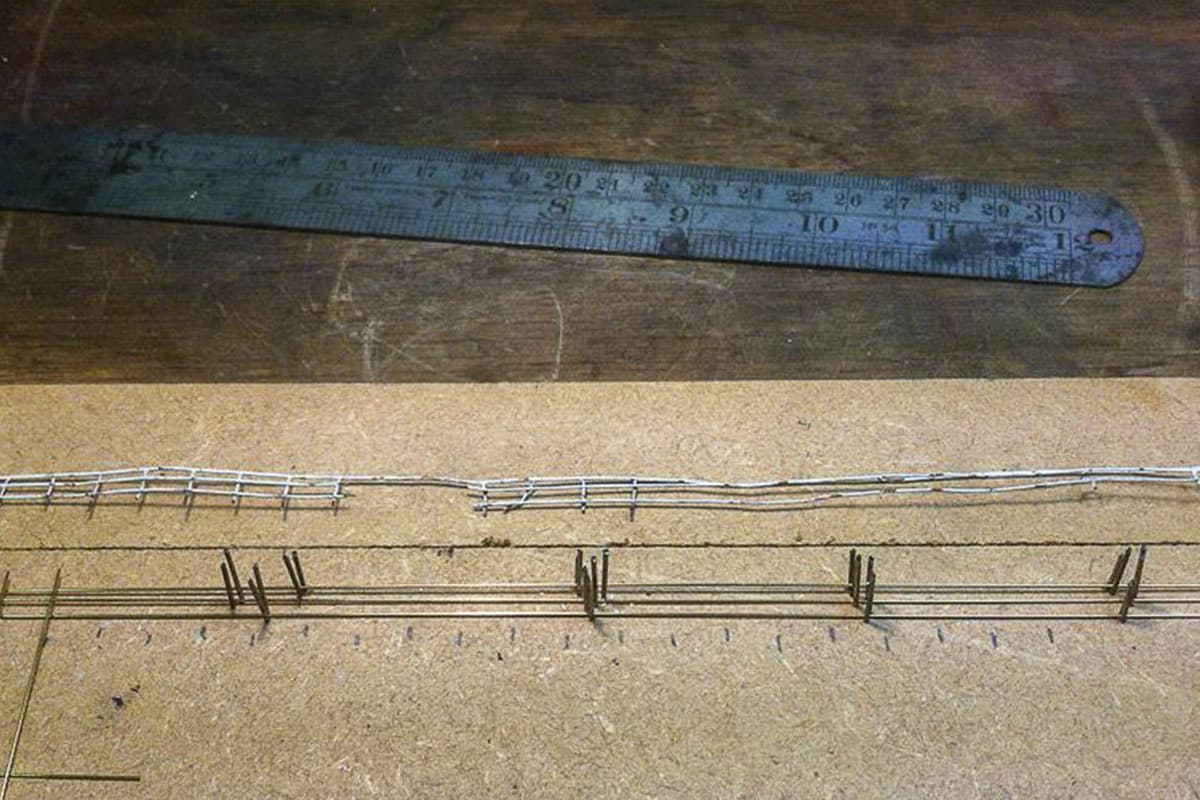

We were able to use a pair of fine pliers to reshape a lot of railings and pipeline that had seemed irretrievably distorted.

To replicate the original railing design, we created a special jig. Lengths of straight brass were carefully lead-soldered together to form a new length of railing. Two of the original ladders were missing, and replicas were created using a similar process.

These newly created elements, along with any areas of paint loss, were then toned in using acrylic paints, mixed to accurately match the original colour scheme.